Technology

Unique Features of PTFE Fuel Line

PTFE fuel lines, also known as Polytetrafluoroethylene fuel lines, offer several advantages over traditional rubber hoses. Some of the key features of evil energy fuel line include:

- High Temperature Resistance

PTFE fuel lines have higher temperature tolerances than rubber hoses, making them less susceptible to heat damage, with the ability to maintain good working performance at a wide temperature range, typically from -60°C to 230°C. - Corrosion Resistance

PTFE hoses are corrosion-resistant and compatible with UV or ozone exposure, reducing the chance of corrosion. This property makes them suitable for use in applications where they are exposed to corrosive chemicals, such as in the automotive and chemical industries. - Low Permeability and Vapor Barrier

PTFE acts as a vapor barrier, preventing fuel vapors and odors from seeping out, making it an ideal choice for applications where a preventing gas odor from permeating the hose is important. - Lightweight

PTFE hoses are light in weight compared to rubber hoses, making them suitable for applications where weight is a critical factor, such as in the aerospace industry.

The advantages of using ptfe fuel lines over rubber fuel line

The advantages of using PTFE fuel lines over rubber 6an fuel line include:

- Chemical Resistance

PTFE hoses are highly resistant to various fluids and chemicals, including gas, ethanol, transmission fluid, brake fluid, power steering fluid, and antifreeze. - Temperature Resistance

PTFE fuel lines have a higher temperature tolerance than rubber hoses, making them less susceptible to heat damage, with the ability to maintain good working performance at a wide temperature range, typically from -60°C to 230°C. - Professional Look and Lightweight

PTFE hoses, especially when made with nylon braiding or stainless steel, provide a more professional look compared to rubber hoses. They are also lightweight, making them suitable for applications where weight is a critical factor, such as in the aerospace industry.

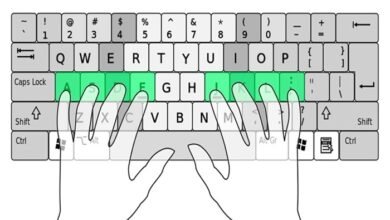

Tools that are Needed to Install PTFE Fuel Lines

- Used to secure the hose and fittings during assembly.

- With a polished face to avoid marking the anodized finish.

- Such as 3-in-1 or similar, for lubricating the threads on the fittings.

- Such as a junior hacksaw, for cutting the hose.

- To gently expand the hose’s inner diameter and assist in fitting installation.

- Used to mark the cut position on the PTFE hose.

- For cutting and handling the hose and fittings.

- For cleaning away any burrs from the PTFE tube.

- For safety during the installation process.

- To wipe off excess oil during the assembly.

Are There any Safety Precautions to take when Installing PTFE Fuel Lines

- Handle with Care

During installation, avoid kinks, twists, or damage to the hose. - Avoid Open Flames

Never expose a fuel hose to an open flame, especially to a fuel hose assembly that has already been exposed to any kind of fuel. - Use Compatible Fittings

Use compatible fittings and secure connections to prevent leaks. - Regularly Inspect the Hose

Regularly inspect the hose for signs of wear, degradation, or leaks. - Clean the Hose

Clean the hose as per the manufacturer’s recommendations to maintain its cleanliness and integrity. - Use Personal Protective Equipment

Wear gloves and glasses for safety during the installation process.